THE SAILS

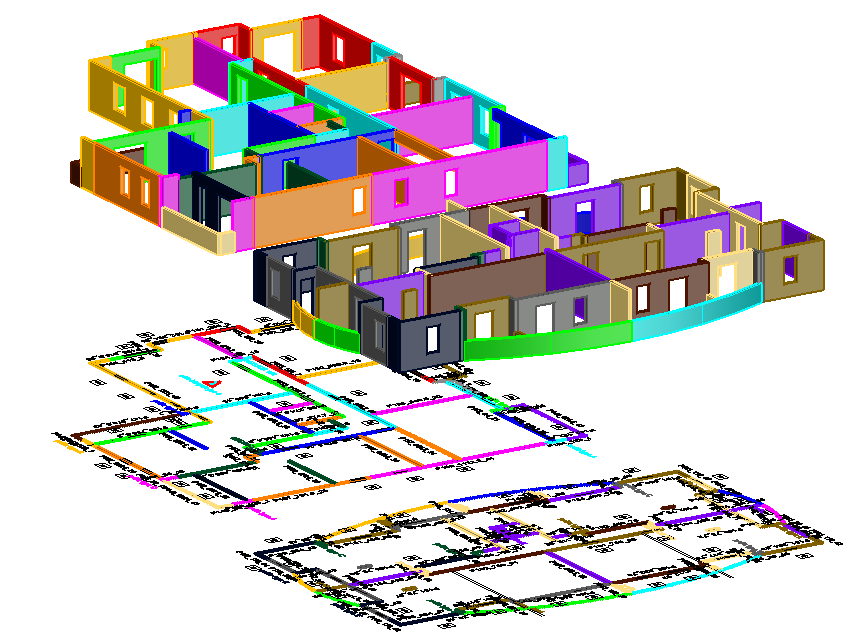

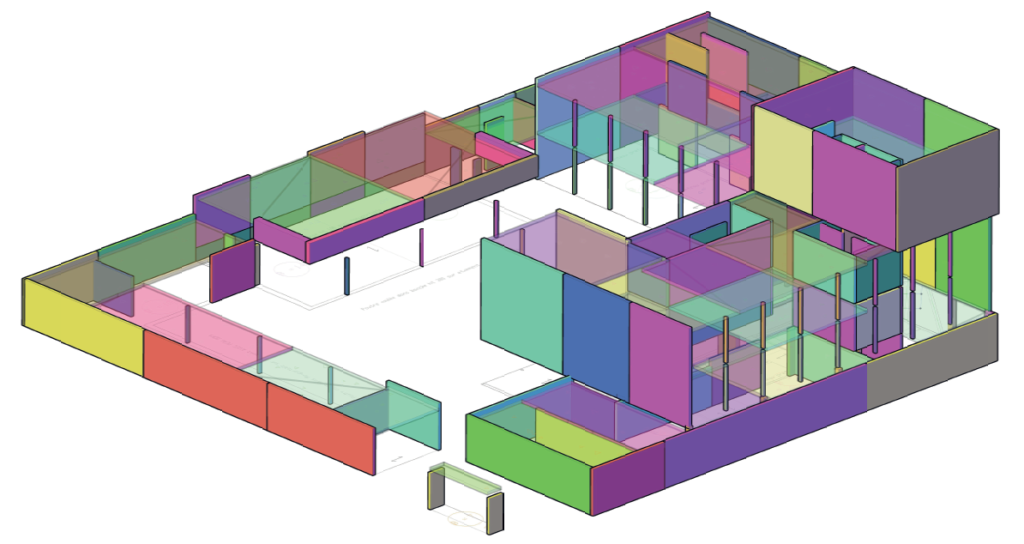

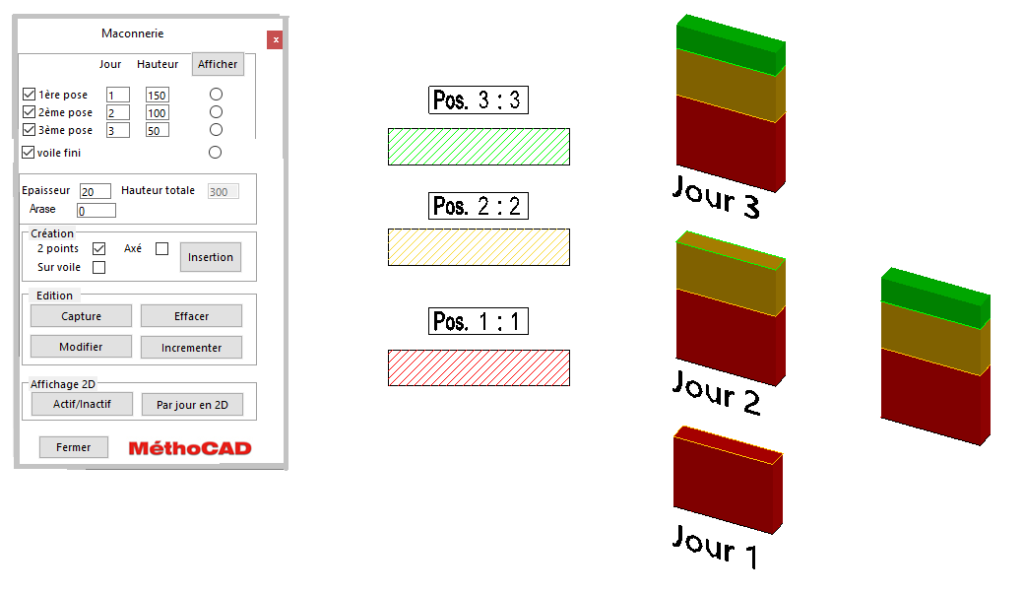

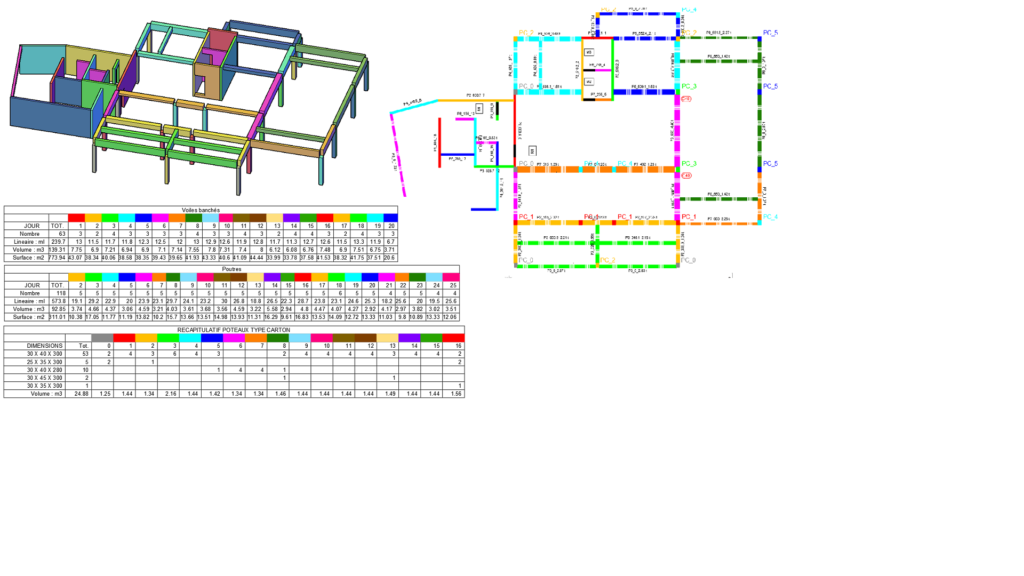

In collaboration with the site manager, the user defines the wall casting cycle from the AutoCAD background plan provided by the design office.

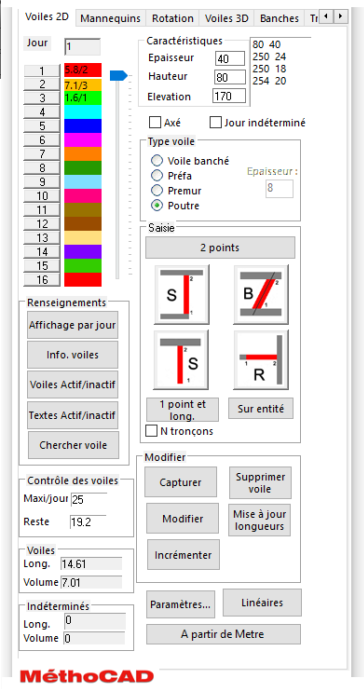

The sails are inserted using a dialog box where the user enters the characteristics of the veil, thickness, height, bottom edge and the casting day.

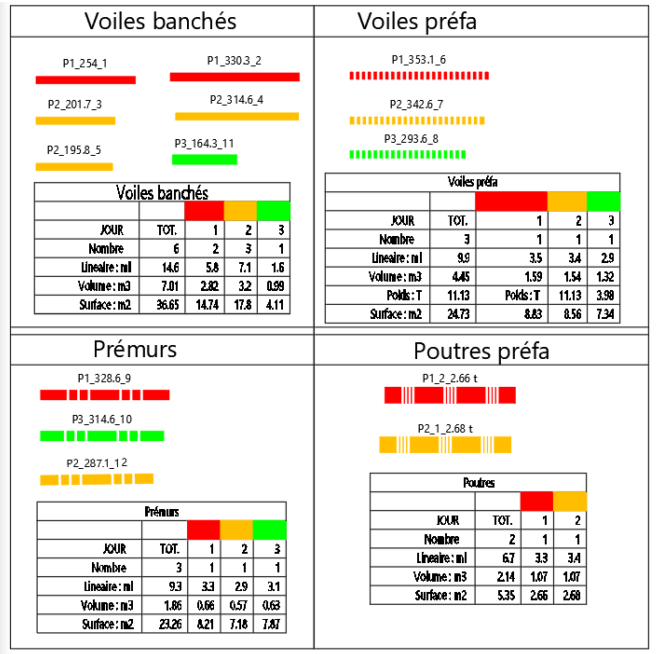

A user-customizable color is assigned to each day. It is possible to insert 3 types of sails: paneled, prefabricated and pre-walled, which are differentiated using types of lines.

The cumulative lengths cast per day and the number of sails are displayed in real time in the dialog box allowing the user to control the entry and ensure a constant average linear throughout the cycle and ‘an equivalent number of sails every day.

The sails can be modified at any time of entry, casting day, thickness, height, length. Linear and volumes are updated automatically.

It is possible to display the cycle day by day to check its consistency. The height / thickness pairs of values are displayed in the box, avoiding having to re-enter them for each wall.

In case of late casting on the site, the sails can be modified by a simple click by giving the number of days of delay and the day of departure. 3D generation is automatic, which can be useful for sails of varying heights.